Metal pipe fabrication is essential in many industries. In Saudi Arabia, it holds a significant place in the economy.

Saudi Arabia is rapidly advancing in infrastructure and industry. Metal pipe fabrication is a key player in this progress. From oil and gas to construction, metal pipes are everywhere. Skilled fabricators in the country ensure high-quality products. They meet the demands of both local and international markets.

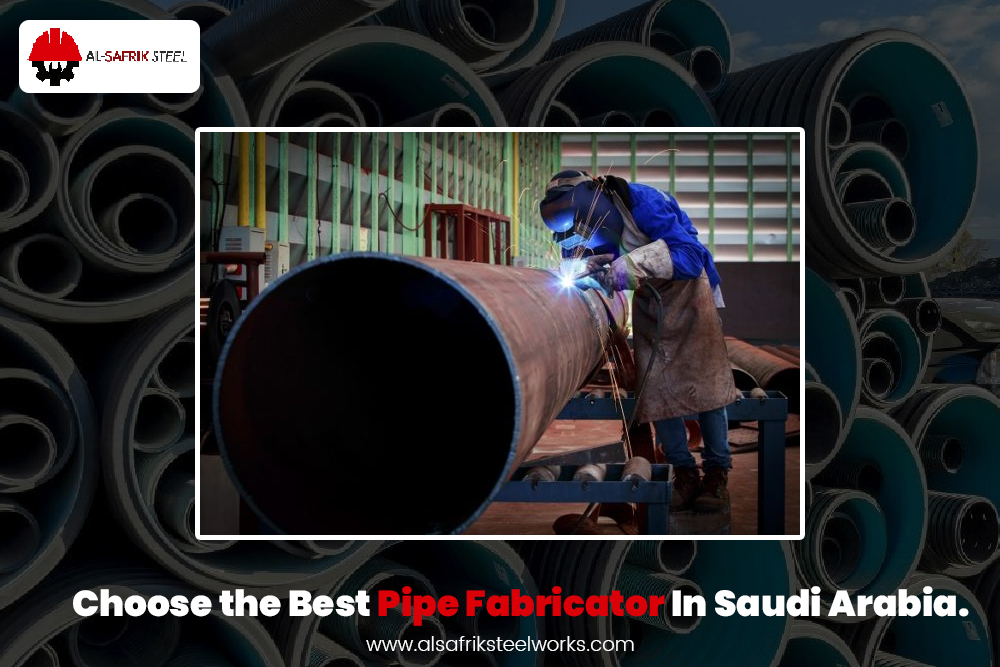

The fabrication process involves cutting, bending, and assembling. This creates strong and durable metal pipes. Saudi Arabia’s strategic location also aids in exporting these products. With modern technology and skilled labor, the metal pipe fabrication industry is thriving. Discover how this sector supports the nation’s growth and what makes it unique.

Introduction To Metal Pipe Fabrication

Metal pipe fabrication is a crucial industry in Saudi Arabia. This process involves creating pipes from raw metal materials. These pipes are essential for various sectors like construction, oil, and gas. The demand for metal pipes is growing rapidly. Understanding this process helps appreciate its significance.

Historical Context

Metal pipe fabrication has deep roots in Saudi Arabia. Early methods were manual and labor-intensive. Workers used simple tools and techniques. The industry started gaining momentum in the mid-20th century. Oil discoveries in the 1930s fueled the need for metal pipes. This led to the growth of local fabrication facilities. Over time, technology improved the processes.

Modern Innovations

Today, the metal pipe fabrication industry is highly advanced. Saudi Arabia uses state-of-the-art technology in its fabrication plants. Automation plays a significant role in modern production. Robots and advanced machinery ensure precision and efficiency. These innovations have reduced the time and cost of production.

Computer-Aided Design (CAD) is another key advancement. Engineers use CAD to design complex pipe systems. This ensures accuracy and reduces errors. Quality control is also more rigorous now. Modern techniques guarantee high-quality products that meet international standards.

Environmental sustainability is becoming a focus. Many fabrication plants are adopting green practices. These include recycling and reducing waste. Such efforts help in conserving resources and protecting the environment.

Credit: alsafriksteelworks.com

Importance Of Precision Engineering

Precision engineering is crucial in metal pipe fabrication. It ensures the highest quality and reliability of pipes. This is especially important in Saudi Arabia, where industries demand robust infrastructure. Precision engineering involves detailed planning and exact measurements. This minimizes errors and enhances efficiency.

Quality Standards

Saudi Arabia adheres to strict quality standards in metal pipe fabrication. These standards ensure the durability and safety of pipes. Compliance with international norms is essential. It guarantees the pipes can withstand harsh conditions.

High-quality standards include:

- ISO certifications

- Regular inspections

- Material testing

Meeting these standards is vital for maintaining trust and reliability in the industry.

Technological Advancements

Technological advancements have transformed metal pipe fabrication. Modern machinery and tools enhance precision and efficiency. Automation plays a significant role in the process. It reduces human errors and speeds up production.

Key technologies include:

- Computer Numerical Control (CNC) machines

- Robotic welding

- Advanced cutting tools

These technologies ensure that each pipe meets exact specifications. This is crucial for large-scale industrial applications.

Major Industries Relying On Metal Pipes

Metal pipe fabrication is crucial in Saudi Arabia’s industrial landscape. Various sectors depend on these pipes for their operations. This section explores the major industries relying on metal pipes.

Oil And Gas

The oil and gas industry in Saudi Arabia heavily relies on metal pipes. These pipes are used for transporting crude oil and natural gas. They ensure safe and efficient movement of these resources. Metal pipes are also essential in drilling operations. They withstand high pressure and extreme temperatures. This makes them ideal for the harsh environments of oil fields.

Construction

The construction industry also benefits from metal pipe fabrication. Metal pipes are used in building infrastructure. They support the framework of residential and commercial buildings. In addition, they are used in plumbing systems. Metal pipes ensure a reliable water supply and waste disposal system. They also play a role in heating and cooling systems. Their durability and strength make them a preferred choice in construction projects.

Credit: alsafriksteelworks.com

Key Players In Saudi Arabia

Metal pipe fabrication in Saudi Arabia is a booming industry. This is due to the country’s rich oil and gas reserves. Several key players dominate this field. These companies ensure high standards and reliable supply. Let’s explore these industry leaders and their partnerships.

Leading Companies

Several companies stand out in metal pipe fabrication in Saudi Arabia. One of the most prominent is Saudi Aramco. Known for its vast resources, Saudi Aramco leads the industry. They ensure top-quality products and services.

Another leading company is SABIC. This giant offers a wide range of fabricated metal pipes. Their products meet global standards. They have a strong presence in the international market.

Al-Qahtani Pipe Coating Industries also plays a significant role. They specialize in pipe coating and fabrication. Their expertise ensures durable and reliable pipes.

Industry Partnerships

Partnerships are crucial in the metal pipe fabrication sector. Saudi Aramco collaborates with international firms. These partnerships bring advanced technology and expertise.

SABIC also forms strategic alliances. They work with global leaders in metal fabrication. These partnerships enhance their product quality and market reach.

Al-Qahtani Pipe Coating Industries partners with technology providers. They aim to improve their coating techniques. These collaborations ensure they stay ahead in the market.

Fabrication Techniques

Metal pipe fabrication in Saudi Arabia involves a variety of techniques. These techniques ensure the pipes meet industry standards. The two main methods are welding and cutting. Each technique has its own set of advantages and specific applications. Understanding these can help in selecting the right method for any project.

Welding Methods

Welding joins metal parts together. In Saudi Arabia, several welding methods are popular:

- Shielded Metal Arc Welding (SMAW): Also known as stick welding. It uses an electrode and electric current.

- Gas Tungsten Arc Welding (GTAW): Known as TIG welding. It uses a tungsten electrode and inert gas.

- Gas Metal Arc Welding (GMAW): Called MIG welding. It uses a wire feed and inert gas.

Each method has its own benefits and is chosen based on the project’s requirements. For instance, SMAW is versatile and cost-effective. TIG welding offers high-quality results, while MIG welding is fast and efficient.

Cutting Technologies

Cutting technologies shape the metal pipes. In Saudi Arabia, the following cutting methods are widely used:

- Plasma Cutting: Uses a high-speed jet of plasma. It cuts through electrically conductive materials.

- Laser Cutting: Employs a high-powered laser beam. It provides precise cuts with minimal waste.

- Oxy-Fuel Cutting: Uses fuel gas and oxygen. It is suitable for cutting thick metal sections.

These cutting technologies ensure the pipes are cut to the desired dimensions. They also help in achieving smooth edges and accurate shapes. Plasma cutting is fast and suitable for various metals. Laser cutting offers high precision, while oxy-fuel cutting is ideal for heavy-duty tasks.

Challenges In Metal Pipe Fabrication

Metal pipe fabrication in Saudi Arabia is a crucial part of the construction and oil industries. Yet, it faces several significant challenges. These challenges can affect project timelines, costs, and the overall quality of the fabricated products. Understanding these challenges can help in finding effective solutions. Below are some of the main challenges in metal pipe fabrication.

Material Sourcing

Sourcing the right materials is a major challenge in metal pipe fabrication. The quality of the metal is vital for durability and performance. In Saudi Arabia, finding high-quality metal can sometimes be difficult. Importing materials often leads to increased costs and delays. Additionally, local suppliers may not always have the required specifications. This can further complicate the sourcing process.

A reliable supply chain is essential. Any disruption can halt the entire fabrication process. Therefore, companies must build strong relationships with trustworthy suppliers. Ensuring the availability of quality metal is a continuous effort. Proper planning and inventory management can mitigate some of these challenges.

Skilled Labor Shortages

Another significant challenge is the shortage of skilled labor. Metal pipe fabrication requires specialized skills. Experienced welders, fitters, and fabricators are in high demand. In Saudi Arabia, there is a notable gap between demand and supply. This shortage can slow down projects and increase costs.

Training programs are essential to address this issue. Investing in training can help develop the required skills locally. Companies should also focus on retaining skilled workers. Providing competitive salaries and benefits can reduce turnover rates. A stable and skilled workforce is key to successful metal pipe fabrication.

| Challenge | Impact | Possible Solutions |

|---|---|---|

| Material Sourcing | Delays and Increased Costs | Build Strong Supplier Relationships |

| Skilled Labor Shortages | Slow Project Timelines | Invest in Training Programs |

Addressing these challenges is critical for the success of metal pipe fabrication projects. Effective strategies can lead to smoother operations and better outcomes.

Future Of Metal Pipe Fabrication

The future of metal pipe fabrication in Saudi Arabia is bright. It is driven by technology, sustainability, and innovation. This industry is evolving rapidly to meet new demands. Companies are investing in advanced technologies to stay competitive.

Emerging Trends

New trends are shaping metal pipe fabrication. Automation is a key trend. It increases efficiency and reduces costs. Robots and AI are transforming the production process. 3D printing is another trend. It allows for more complex designs and faster production times. Digital twins are also gaining popularity. They help in monitoring and optimizing the fabrication process.

Sustainability Focus

Sustainability is at the forefront of the industry. Companies are adopting green practices. They aim to reduce waste and energy use. Recycling is a major focus. Recycled metals are being used to produce new pipes. This reduces the environmental impact. Energy-efficient machines are also being used. They help in cutting down energy consumption. Sustainable materials are being explored. This ensures a greener future for metal pipe fabrication.

| Trend | Benefit |

|---|---|

| Automation | Increases efficiency and reduces costs |

| 3D Printing | Allows complex designs and faster production |

| Digital Twins | Optimizes the fabrication process |

| Recycling | Reduces environmental impact |

| Energy-efficient Machines | Cuts down energy consumption |

The future of metal pipe fabrication in Saudi Arabia is promising. It is set to thrive with emerging trends and a strong focus on sustainability.

Case Studies

Case studies provide valuable insights into metal pipe fabrication projects in Saudi Arabia. These examples showcase the skills and expertise of local companies. They highlight successful projects and innovative solutions in the industry.

Successful Projects

One notable project involved constructing a large oil refinery. The fabrication team used high-quality materials. They ensured the pipes met all safety and performance standards. The project was completed on time. It also stayed within budget.

Another project focused on a desalination plant. This plant provides clean water to thousands of people. The fabrication of the pipes required precision. The team achieved this through meticulous planning. They also maintained close coordination with the client.

Innovative Solutions

In one case, a company faced a unique challenge. They needed to fabricate pipes for a new chemical plant. The pipes had to withstand extreme temperatures. The team developed a special alloy. This alloy improved the pipes’ durability.

Another example involved a power plant. The plant required pipes with a specific curvature. Traditional methods could not achieve this. The team used advanced bending techniques. These techniques ensured the pipes fit perfectly.

Credit: zamilsteel.com

Frequently Asked Questions

What Is Metal Pipe Fabrication?

Metal pipe fabrication involves cutting, bending, and assembling metal pipes to create structures. It’s essential for various industries in Saudi Arabia.

Why Is Metal Pipe Fabrication Important?

Metal pipe fabrication ensures the durability and efficiency of piping systems. It is crucial for construction, oil, gas, and other industries.

What Materials Are Used In Metal Pipe Fabrication?

Common materials include stainless steel, carbon steel, and aluminum. These materials offer strength and corrosion resistance.

How To Choose A Metal Pipe Fabrication Company?

Look for experience, certifications, and reviews. Ensure they use advanced technologies and follow industry standards.

Conclusion

Saudi Arabia excels in metal pipe fabrication. Skilled workers and modern tools ensure quality. The industry supports various sectors like oil, gas, and construction. Local businesses benefit from reduced costs and quick delivery. High standards and precision are their hallmarks.

As demand grows, so does innovation. Investing in metal pipe fabrication here promises good returns. Saudi Arabia remains a strong player in this field. Explore the possibilities and see the results firsthand.