Sheet metal fabrication is a vital industry in Saudi Arabia. This process turns flat sheets of metal into high-quality products.

Saudi Arabia’s booming construction and industrial sectors fuel the demand for sheet metal fabrication. This process involves cutting, bending, and assembling metal to create structures or parts. Key industries, such as oil and gas, automotive, and construction, rely heavily on these metal products.

Understanding the sheet metal fabrication process in Saudi Arabia is crucial for anyone in these fields. It’s a blend of traditional techniques and modern technology, ensuring high precision and durability. Let’s explore how this process shapes the backbone of various industries in the Kingdom.

Introduction To Sheet Metal Fabrication

Sheet metal fabrication is a vital industry in Saudi Arabia. It involves transforming flat sheets of metal into various shapes and structures. This process is used in many sectors such as construction, automotive, and aerospace.

What Is Sheet Metal Fabrication?

Sheet metal fabrication involves cutting, bending, and assembling metal sheets. Each step has its own techniques and tools. Common metals used include steel, aluminum, and copper.

- Cutting: Sheets are cut to the desired shape using lasers, shears, or saws.

- Bending: Sheets are bent into shapes using press brakes or other tools.

- Assembling: Pieces are joined together using welding, rivets, or adhesives.

This process allows for the creation of complex and precise metal parts. It is essential for building everything from small brackets to large machinery.

Importance In Modern Industry

In Saudi Arabia, sheet metal fabrication plays a crucial role in modern industry. It is used in the construction of buildings, infrastructure, and vehicles. The country’s rapid development has increased demand for skilled fabricators.

Some key benefits include:

- Durability: Fabricated metal parts are strong and long-lasting.

- Cost-Effectiveness: Metal sheets can be mass-produced and customized.

- Versatility: Applicable in various industries such as construction and automotive.

The fabrication process supports Saudi Arabia’s vision of becoming a global industrial leader. It provides jobs and boosts the economy.

History Of Sheet Metal Fabrication In Saudi Arabia

The history of sheet metal fabrication in Saudi Arabia is rich and fascinating. This process has evolved over the years, impacting many industries. Let’s explore its journey from early developments to modern advancements.

Early Developments

Sheet metal fabrication began in Saudi Arabia in the early 20th century. Traditional techniques like hammering and cutting by hand were common. Skilled artisans created tools, household items, and simple machinery components.

During this period, manual labor was the primary method. Workshops were small and locally operated. The demand for metal items increased, prompting the need for more efficient methods.

Modern Advancements

In recent decades, modern technology has transformed sheet metal fabrication. Automated machinery now performs tasks that once required manual effort. Computer-aided design (CAD) systems enhance precision and efficiency.

Today, Saudi Arabia’s fabrication industry uses advanced techniques. Laser cutting, CNC machining, and robotic welding are standard practices. These methods improve product quality and reduce production time.

The industry also embraces sustainable practices. Recycling and minimizing waste are now priorities. This shift reflects a growing awareness of environmental responsibility.

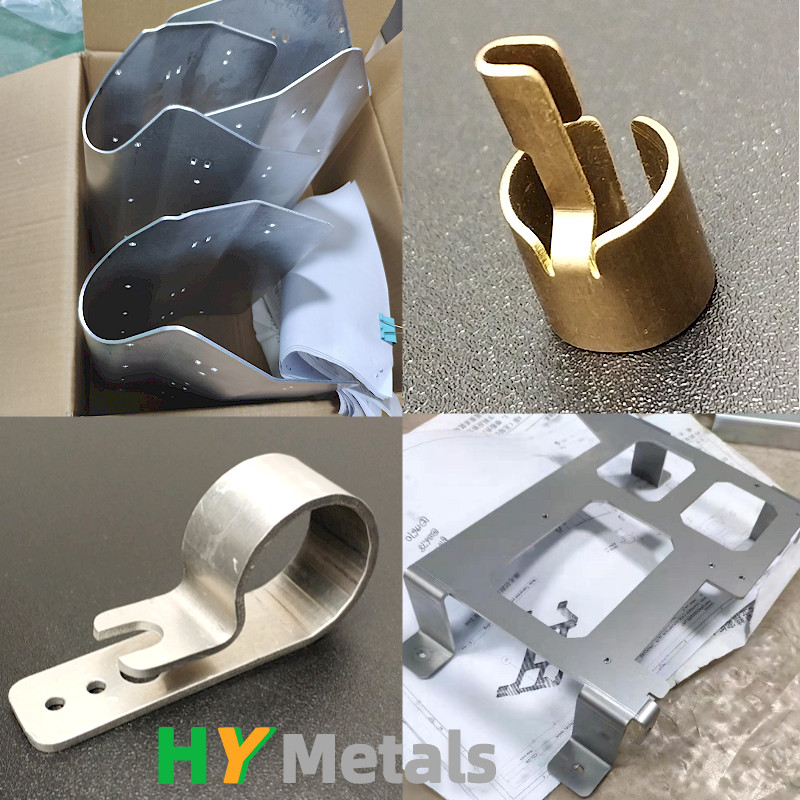

Types Of Sheet Metal Used

In Saudi Arabia, the sheet metal fabrication process is vital for various industries. Understanding the types of sheet metal used is essential for selecting the right material for your projects. Each type has its unique properties and applications. Let’s explore the most common types of sheet metal used in fabrication.

Steel

Steel is one of the most widely used metals in fabrication. It is known for its strength and durability. Steel can be categorized into different types:

- Carbon Steel: This type is strong and cost-effective. It is used in construction and machinery.

- Stainless Steel: It resists corrosion and is used in medical equipment and kitchen appliances.

- Galvanized Steel: This steel is coated with zinc to prevent rust. It is ideal for outdoor applications.

Steel is versatile and available in various thicknesses and grades. Its use depends on the project requirements.

Aluminum

Aluminum is lightweight and resistant to corrosion. It is popular in the aerospace and automotive industries. Aluminum can be categorized into:

- Pure Aluminum: It is soft and used for electrical applications.

- Alloyed Aluminum: This type is mixed with other metals to enhance strength. It is used in construction and transportation.

Aluminum is easy to work with and recyclable. It offers a good balance of strength and weight.

Copper

Copper is known for its excellent conductivity. It is used in electrical and plumbing applications. Copper can be categorized into:

- Pure Copper: This type is used in electrical wiring and components.

- Alloyed Copper: It is mixed with other metals like zinc or tin. It is used in coins and musical instruments.

Copper is also valued for its aesthetic appeal. It is used in decorative and architectural elements.

Credit: www.hymetalproducts.com

Key Fabrication Processes

Sheet metal fabrication is a critical process in Saudi Arabia’s manufacturing industry. It involves several key steps to transform raw metal into functional parts. Understanding these processes helps in producing high-quality products.

Cutting

Cutting is the first step in sheet metal fabrication. It involves slicing large sheets into smaller, manageable pieces. Techniques like laser cutting, shearing, and plasma cutting are common. Precision in cutting is vital for the quality of the final product.

Bending

Bending follows cutting and shapes the metal into desired forms. Machines like press brakes are used to bend the metal accurately. Proper bending ensures the parts fit together perfectly in the assembly stage. Skilled operators are crucial for precise bends.

Welding

Welding joins different metal pieces together. It uses heat and pressure to fuse the metals. Common welding methods include MIG, TIG, and spot welding. Strong welds ensure the durability and integrity of the product.

Assembling

Assembling is the final step in the fabrication process. It involves putting together the cut, bent, and welded parts. Fasteners, rivets, and adhesives are often used. Proper assembly ensures the final product meets design specifications and functions correctly.

Technological Innovations

The sheet metal fabrication process in Saudi Arabia has undergone significant transformations. Technological innovations have played a crucial role in enhancing efficiency and precision. Modern techniques have replaced traditional methods, enabling higher productivity and better quality.

Cnc Machining

CNC machining stands for Computer Numerical Control. This technology automates the control of machine tools. By using coded instructions, CNC machines can precisely cut, shape, and drill metal sheets. This ensures consistent and accurate results, reducing human error.

The benefits of CNC machining include:

- Increased precision

- Reduced material waste

- Faster production times

- Enhanced safety

Laser Cutting

Laser cutting uses a high-powered laser to cut materials. This method is highly accurate and efficient. It is suitable for cutting complex shapes and designs. Laser cutting is faster than traditional methods, reducing production time and costs.

The advantages of laser cutting are:

- High precision

- Clean cuts with smooth edges

- Minimal material waste

- Ability to cut intricate designs

Automation

Automation involves the use of machines and software to perform tasks without human intervention. In sheet metal fabrication, automation has streamlined many processes. It has improved consistency and speed in production.

Key benefits of automation include:

- Reduced labor costs

- Increased production speed

- Improved product quality

- Enhanced workplace safety

These technological innovations have revolutionized the sheet metal fabrication process in Saudi Arabia. They have made the industry more efficient and competitive.

Credit: trdsf.com

Applications In Various Industries

The sheet metal fabrication process plays a crucial role in various industries in Saudi Arabia. This process involves cutting, bending, and assembling metal sheets into different shapes and sizes. Its versatility makes it an essential component in many sectors. Below, we explore its applications in three key industries.

Construction

In the construction industry, sheet metal is used for various purposes. It is commonly used for roofing, gutters, and ducts. Architects and builders prefer sheet metal for its strength and durability. It also offers flexibility in design. This makes it ideal for both residential and commercial buildings. Sheet metal can withstand harsh weather conditions. It provides a long-lasting solution for structural needs.

Automotive

The automotive industry relies heavily on sheet metal fabrication. Car bodies, chassis, and other components are often made from sheet metal. It offers excellent strength-to-weight ratio. This helps in improving fuel efficiency. Manufacturers use sheet metal for its ease of manufacture and cost-effectiveness. It allows for mass production of vehicle parts. This process ensures consistency and quality in every piece.

Aerospace

Sheet metal fabrication is vital in the aerospace sector. Aircraft structures and components often use sheet metal. Its high strength and lightweight properties are essential. This helps in achieving better flight performance and safety. Precision is crucial in aerospace applications. Sheet metal fabrication provides the accuracy needed. It ensures that each component meets strict industry standards. This makes it a preferred choice in aerospace engineering.

Challenges Faced In Saudi Arabia

Sheet metal fabrication in Saudi Arabia faces several challenges. Each challenge affects the industry differently. This section explores these challenges in detail.

Resource Scarcity

Resource scarcity is a major challenge. Saudi Arabia imports many raw materials. This increases costs and delays projects. It also affects the overall quality of products. The reliance on imported resources can disrupt supply chains. This makes the industry less competitive.

Technical Expertise

Technical expertise is another significant issue. There is a shortage of skilled workers in the field. Many technicians lack advanced training. This impacts the efficiency of fabrication processes. It also results in higher error rates and lower productivity. Investing in training programs could help address this problem.

Market Competition

Market competition is intense. Many international companies operate in Saudi Arabia. They often have better technology and more resources. This makes it hard for local businesses to compete. The high competition puts pressure on prices and profit margins.

To succeed, local companies must innovate. They need to adopt advanced technologies. They should also focus on improving quality and customer service. This can help them stand out in the competitive market.

Credit: www.protolabs.com

Future Trends

Saudi Arabia’s sheet metal fabrication industry is evolving rapidly. Several future trends are shaping this sector. These trends include sustainability efforts, integration of AI, and global market impact. Each of these trends promises significant improvements and opportunities for growth.

Sustainability Efforts

Sustainability is becoming a key focus in sheet metal fabrication. Companies are looking for ways to reduce waste and energy consumption. This not only helps the environment but also reduces costs.

- Using recycled materials

- Implementing energy-efficient machinery

- Adopting green manufacturing practices

These efforts contribute to a more sustainable industry. They also help companies meet regulatory requirements and improve their market reputation.

Integration Of Ai

The integration of AI is transforming the fabrication process. AI technologies are enhancing precision and efficiency. They help in predicting maintenance needs and improving quality control.

- Automated design and production

- Predictive maintenance

- Enhanced quality control

AI-driven systems can analyze vast amounts of data. This leads to better decision-making and optimized processes.

Global Market Impact

The global market impact of Saudi Arabia’s sheet metal fabrication industry is significant. The country is becoming a major player in the global market. This is due to its strategic location and advancements in technology.

| Factor | Impact |

|---|---|

| Strategic Location | Easy access to international markets |

| Technology Advancements | Increased production capacity |

| Quality Standards | Enhanced global competitiveness |

These factors are enabling Saudi Arabia to compete on a global scale. They also open up new opportunities for exports and partnerships.

Frequently Asked Questions

What Is Sheet Metal Fabrication?

Sheet metal fabrication is a process of forming metal sheets into desired shapes. It involves cutting, bending, and assembling. This process is used in various industries, including automotive and construction.

Why Is Sheet Metal Fabrication Important?

Sheet metal fabrication is crucial for creating durable and custom metal parts. It allows for precise manufacturing. This process ensures high-quality products for various applications.

What Materials Are Used In Sheet Metal Fabrication?

Common materials used in sheet metal fabrication include steel, aluminum, and copper. These materials offer strength and versatility. Selection depends on the application and desired properties.

What Are The Main Steps In Sheet Metal Fabrication?

The main steps in sheet metal fabrication include cutting, bending, and assembling. Cutting shapes the metal, bending forms angles, and assembling joins parts. Each step is essential for creating the final product.

Conclusion

Sheet metal fabrication in Saudi Arabia plays a crucial role in various industries. This process ensures high-quality products and supports economic growth. Skilled professionals use advanced techniques to meet diverse needs. With a focus on precision, the industry continues to evolve.

Companies aim to deliver efficient and reliable services. Understanding this process helps in appreciating its impact on everyday life. The future of sheet metal fabrication in Saudi Arabia looks promising. Advances in technology will drive further innovation and efficiency. Stay informed and appreciate the craftsmanship involved.