Metal fabrication is vital in Saudi Arabia’s industrial landscape. It supports various sectors, including construction, automotive, and energy.

In Saudi Arabia, metal fabrication encompasses multiple techniques and processes. These methods help create structures, parts, and products from raw metal materials. Understanding the types of metal fabrication used in Saudi Arabia can provide insights into the country’s industrial capabilities and innovations.

Whether you are a business owner, engineer, or student, knowing these processes is crucial. This knowledge can aid in making informed decisions, improving designs, and enhancing production efficiency. Dive deeper into this topic to explore the diverse world of metal fabrication in Saudi Arabia.

Credit: www.protolabs.com

Introduction To Metal Fabrication

Metal fabrication is the process of creating metal structures and products. It involves cutting, bending, and assembling metals. This craft transforms raw materials into high-quality items. Metal fabrication is crucial in many industries. These include construction, automotive, and aerospace.

In Saudi Arabia, metal fabrication has a rich history. It continues to play a vital role in the country’s economy. The sector has evolved with advanced technologies. This makes it a key player in modern industry.

History In Saudi Arabia

Saudi Arabia’s metal fabrication history dates back centuries. Early blacksmiths crafted simple tools and weapons. Over time, techniques improved. Today, the industry is highly sophisticated. Modern facilities employ advanced machinery and skilled workers.

The rise of oil in the 20th century boosted the industry. Metal fabrication became crucial for infrastructure and development. The government invested in large-scale projects. This led to the growth of local fabrication companies.

Importance In Modern Industry

Metal fabrication is vital in today’s industrial landscape. It supports the construction of buildings, bridges, and pipelines. Fabricated metals are also used in manufacturing vehicles and machinery.

In Saudi Arabia, the industry supports many sectors. These include construction, automotive, and oil and gas. The demand for high-quality metal products continues to grow. This drives innovation and investment in the sector.

The industry also creates jobs and boosts the economy. Skilled workers are in high demand. This leads to training and education opportunities. The sector’s growth is essential for the country’s Vision 2030 goals. These aim to diversify the economy and reduce oil dependency.

Credit: wavesmetal.wordpress.com

Cutting Techniques

Cutting techniques play a crucial role in metal fabrication. They determine the precision and efficiency of the process. Saudi Arabia has embraced advanced cutting methods to meet the growing demand. These methods ensure high-quality results in various industries.

Laser Cutting

Laser cutting is highly precise. It uses a focused laser beam to cut metals. This technique is ideal for intricate designs. The laser melts, burns, or vaporizes the metal, creating clean cuts. It is widely used in the automotive and aerospace industries. Laser cutting is efficient and reduces material waste.

Plasma Cutting

Plasma cutting is another popular method. It uses an accelerated jet of hot plasma. This jet cuts through electrically conductive materials. Plasma cutting is fast and effective for thick metals. It is commonly used in construction and manufacturing. This technique offers high-speed cutting with minimal distortion.

Bending Methods

Metal fabrication is crucial in Saudi Arabia’s industrial sector. Various bending methods shape metal into desired forms. This section explores two key techniques: press braking and roll bending. Each method has unique applications and advantages.

Press Braking

Press braking is a widely used method in metal fabrication. It involves using a press brake machine to bend metal sheets. The machine applies force to a piece of metal, shaping it to the desired angle.

Press brakes can be manual, hydraulic, or electric. Manual press brakes require human effort to operate. They are suitable for small-scale projects. Hydraulic press brakes use hydraulic fluid to generate force. They offer more power and precision. Electric press brakes are energy-efficient and provide consistent results.

Press braking is ideal for creating precise bends. It is used in industries like construction, automotive, and manufacturing. Common materials include steel, aluminum, and copper.

Roll Bending

Roll bending is another essential technique in metal fabrication. It uses rollers to bend metal into curves or cylindrical shapes. This method is perfect for creating pipes, tubes, and rings.

There are three main types of roll bending machines:

- Three-roll pyramid: The most common type. It has three rollers arranged in a triangular shape.

- Two-roll: Uses two rollers. One roller bends the metal while the other supports it.

- Four-roll: Offers greater precision and control. It has four rollers for better handling.

Roll bending is suitable for large-scale projects. It is often used in the oil and gas industry, construction, and aerospace.

Both press braking and roll bending are crucial in Saudi Arabia’s metal fabrication industry. Understanding these methods helps in selecting the right technique for each project.

Welding Processes

Welding processes are a key part of metal fabrication in Saudi Arabia. They join metal parts together, creating strong and durable products. Different welding techniques are used based on the type of metal and the project requirements. Below are two common welding methods used in the industry.

Mig Welding

MIG welding, or Metal Inert Gas welding, is a popular method. It uses a continuous wire feed to join metals together. The wire acts as both the electrode and filler material. This process is versatile and efficient, making it ideal for various applications.

- Advantages:

- Easy to learn and use

- High welding speeds

- Good for thicker materials

- Disadvantages:

- Not suitable for outdoor use

- Requires a clean surface

- Higher equipment cost

Tig Welding

TIG welding, or Tungsten Inert Gas welding, is another common method. It uses a non-consumable tungsten electrode to produce the weld. This technique is known for its precision and quality. It is often used for more delicate and detailed work.

- Advantages:

- Produces high-quality welds

- Suitable for thin materials

- Allows for precise control

- Disadvantages:

- Slower welding process

- Requires more skill and practice

- Can be more expensive

Machining Techniques

In Saudi Arabia, metal fabrication is a crucial industry. Machining techniques are essential processes in metal fabrication. These techniques transform raw materials into precise components and products. This section explores two primary machining techniques: CNC machining and manual machining.

Cnc Machining

CNC machining stands for Computer Numerical Control machining. This modern technique uses computers to control machine tools. It ensures high precision and consistency in metal fabrication.

Here are some key benefits of CNC machining:

- Accuracy: CNC machines can produce exact designs with minimal errors.

- Efficiency: They can operate continuously, producing parts faster.

- Complexity: They handle intricate designs and complex geometries easily.

CNC machining is widely used in Saudi Arabia for various industries, including automotive, aerospace, and construction.

Manual Machining

Manual machining involves human operators controlling machine tools. This traditional method requires skill and experience. While it is less automated, it offers several advantages:

- Flexibility: Manual machining is suitable for custom, small-batch production.

- Cost-effective: It is often more economical for low-volume projects.

- Adaptability: Operators can make adjustments on the fly, ensuring quality control.

Manual machining remains vital in Saudi Arabia. It is used for prototypes, repairs, and specialized tasks.

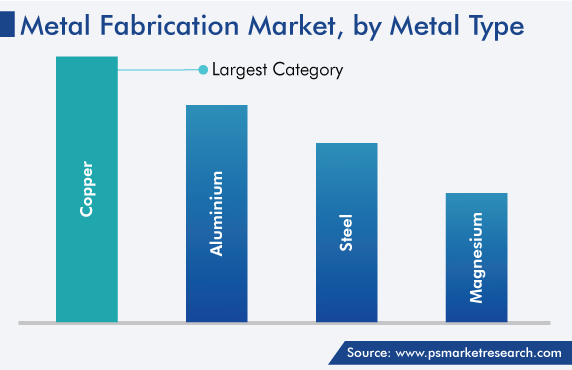

Credit: www.psmarketresearch.com

Innovative Techniques

Saudi Arabia is at the forefront of adopting innovative metal fabrication techniques. These methods are transforming the industry, making processes faster and more precise. Companies are now employing advanced technologies to meet the growing demands of various sectors.

3d Metal Printing

3D metal printing is a breakthrough in metal fabrication. It allows the creation of complex shapes that were once impossible. By using a digital file, printers layer metal powders to form solid objects. This method reduces waste and speeds up production. It’s ideal for custom parts and prototypes.

Water Jet Cutting

Water jet cutting is another advanced technique. It uses high-pressure water mixed with abrasive materials. This stream can cut through metals with great precision. The process is cold, so it doesn’t affect the metal’s properties. This method is perfect for intricate designs and thick materials.

Material Types

Metal fabrication in Saudi Arabia involves various material types. The choice of material impacts the fabrication process and the final product’s quality. Two popular materials used in metal fabrication are steel and aluminum. Each has unique properties and applications.

Steel Fabrication

Steel fabrication is a widely used method in Saudi Arabia. Steel is known for its strength and durability. It is ideal for construction projects, machinery, and infrastructure.

There are different types of steel used in fabrication:

- Carbon Steel: Commonly used due to its hardness and cost-effectiveness.

- Alloy Steel: Contains elements like chromium and nickel to improve properties.

- Stainless Steel: Resistant to rust and corrosion, perfect for medical and food industries.

Steel can be easily welded, cut, and shaped, making it versatile. Its applications range from building skyscrapers to manufacturing vehicles.

Aluminum Fabrication

Aluminum fabrication is another essential process in Saudi Arabia. Aluminum is lightweight, resistant to corrosion, and has good thermal conductivity.

Here are some types of aluminum used in fabrication:

- Pure Aluminum: Soft and ductile, used in electrical applications.

- Aluminum Alloys: Mixed with other elements to improve strength and durability.

- Anodized Aluminum: Treated to increase resistance to corrosion and wear.

Aluminum is easy to mold and shape, making it ideal for aerospace, transportation, and packaging industries. Its lightweight nature also makes it suitable for applications where weight is a concern.

Future Trends

The metal fabrication industry in Saudi Arabia is evolving. Future trends indicate significant changes and advancements. These trends aim to increase efficiency, sustainability, and innovation.

Automation In Fabrication

Automation is becoming a key player in metal fabrication. Robotics and AI are being integrated into various processes. These technologies enhance precision and reduce human error. Automated systems also speed up production and improve safety. This shift is vital for staying competitive in the global market.

Sustainable Practices

Sustainability is gaining importance in metal fabrication. Companies are adopting eco-friendly practices. These include using recyclable materials and reducing waste. Energy-efficient processes are also being implemented. This trend aligns with global environmental goals. It also meets the increasing demand for green products.

Challenges In The Industry

Metal fabrication in Saudi Arabia faces several challenges. These challenges impact the efficiency and output of the industry. Understanding these obstacles can help in finding effective solutions.

Skilled Labor Shortage

There is a shortage of skilled labor in the metal fabrication industry. Many workers lack the necessary training and experience. This shortage affects productivity and quality. Companies struggle to find qualified professionals to fill important roles. Training programs and education need improvement to address this issue.

Technological Advancements

The industry also faces challenges with technological advancements. New technologies require significant investment. Small and medium-sized companies often find it hard to afford these costs. Keeping up with the latest technology is essential for staying competitive. The rapid pace of technological change can overwhelm many businesses. This creates a gap between those who can adapt and those who cannot.

Frequently Asked Questions

What Are Common Metal Fabrication Types In Saudi Arabia?

Common metal fabrication types in Saudi Arabia include welding, cutting, bending, and assembling. These techniques are used across various industries. They help in creating structures, machinery, and other essential components.

Which Industries Use Metal Fabrication In Saudi Arabia?

Industries such as construction, oil and gas, and automotive extensively use metal fabrication in Saudi Arabia. These industries rely on metal fabrication for building infrastructure, machinery, and vehicles.

How Does Metal Cutting Work In Fabrication?

Metal cutting in fabrication involves using tools or machines to remove material from a metal workpiece. This process shapes the metal into the desired form. Techniques include laser cutting, plasma cutting, and waterjet cutting.

What Materials Are Used In Metal Fabrication?

Common materials used in metal fabrication include steel, aluminum, and copper. These materials are chosen for their strength, durability, and versatility. They are suitable for various applications in different industries.

Conclusion

Metal fabrication in Saudi Arabia showcases a rich variety of techniques. These methods range from welding to machining, each serving different needs. The industry supports construction, automotive, and other sectors. Skilled workers and advanced technology ensure quality and precision. Understanding these types helps in choosing the right method for your project.

Saudi Arabia continues to lead in metal fabrication, contributing significantly to its economy. Keep these insights in mind for informed decisions in your ventures.